HDI

What is a HDI?

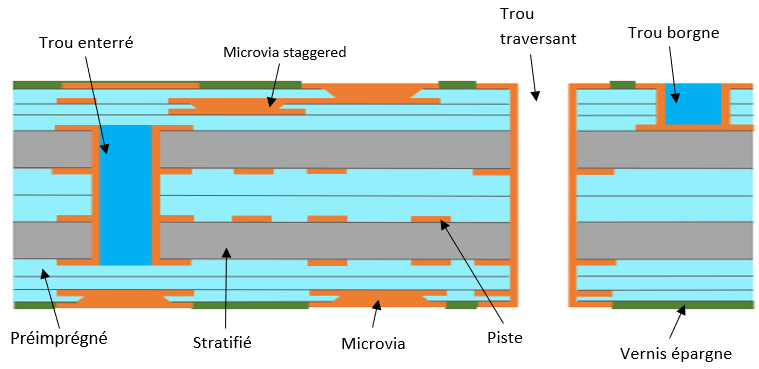

UAn HDI PCB is defined by its high density of interconnections. HDI PCBs have thin traces and isolations, vias and microvias.

What is a buried hole?

A buried hole is a hole between several internal layers. Buried holes are usually drilled mechanically. (see HDI diagram)

What is a blind hole?

A blind hole only goes through part of the PCB, it is a non-through hole. The blind hole is made by mechanical or laser drilling. (see HDI diagram)

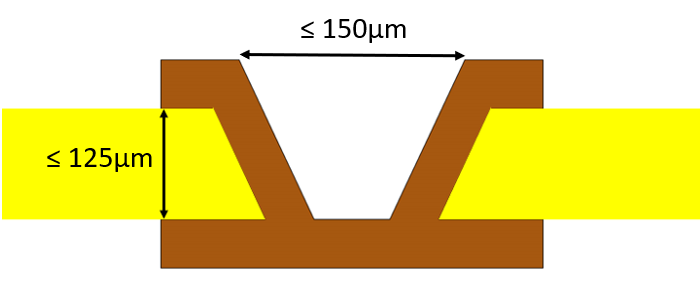

What is a microvia?

LeMicrovias are blind holes drilled with lasers. In most cases, a microvia is a blind hole with a diameter of 150µm or less and a height no greater than its width. The metal plating ratio of the microvia is usually 0.8 to 1.

SBU Definition

Sequential Build Up (SBU) technology is a technology used to create HDI circuits. This technology combines several successive layers in a sequence of holes. It uses buried, blind and microvias technologies to densify the interconnections.

Types of HDI features

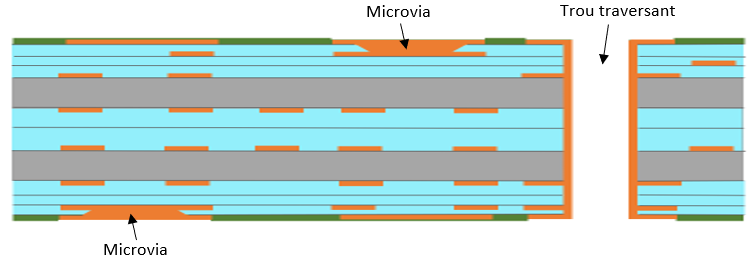

Case I

It includes:

- Metal plated microvias (copper filled or not according to the request) and metal plated through-hole for interconnection

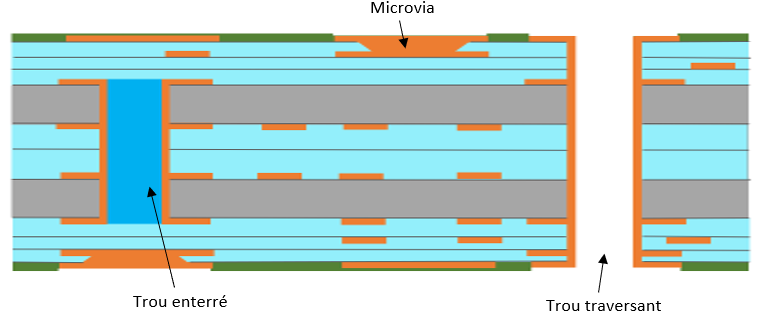

Case II

IIt includes:

- Metal plated microvias (copper filled or not according to the request) and metal plated through-hole for interconnection

- Buried holes

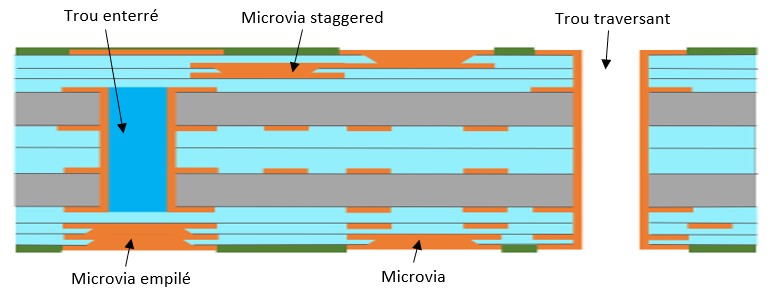

Case III

It includes:

- Metal plated microvias (copper filled or not according to the request) and metal plated through-hole for interconnection

- Buried holes

- Staggered or stacked microvias

Staggered holes may or may not be filled with copper, while stacked holes are necessarily filled with copper.

HDI diagram

Examples of use:

- Automotive

- Smartphones and tablets

- Defence and aeronautics

- Medical

- Laptop computer

- Railway

- Aerospace

For further information, please contact us

Attention, vous utilisez un navigateur peu sûr !

Attention, vous utilisez un navigateur peu sûr !